Custom Built From the Chassis Up

Fold Out Steps

Synergy has developed an enlarged handrail to provide a solid anchor-point for entering and exiting the logging cabin. All handrails are of electro-polished, stainless steel construction and standard on all Synergy trucks.

Under Body Tool Racks

Synergy's under body tool rack has a six tool capacity and uses slick plate to slide tools into place. A full airbag system with stainless steel pins are standard to secure tool transport.

Interior Details - Interior Trim

Synergy installs aluminum trim throughout the interior to provide a complete seal. Positive air pressure is an available option for cabin interiors during transport.

Interior Details - Lighting

Synergy's lighting is all LED and flush mounted. There is also indirect lighting options to provide ease of viewing.

Interior Details - Cabinetry

Synergy fabricates all cabinetry in-house using 1/8” aluminum with large radius corners. Customized interior cabinetry layout is designated by each customer’s needs. All cabinetry is powder coated for longer wear life in customer selected colors. Corian counter tops are standard.

Interior Details - Operator Console

Synergy’s operator console is ergonomically designed for comfort during extended wireline operations. The operator console is laid out according to each customer’s specifications.

Cabin Construction

The walls are foam with 2” of R42 material for insulation and sound proofing. Interior wall mount supports are inserted and welded for rigid mounting the selected custom cabinetry.

Cabin Construction

Synergy utilizes superior products in cabin construction, 1/8” walls, 2” channels and custom corner extrusions.

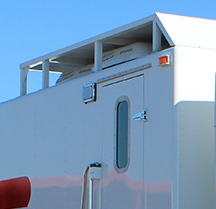

Desert Shield

Synergy’s desert shield is installed above the cabin roof mounted A/C units, the shield was developed to aid the A/C units cooling performance in severe desert conditions.

Bumper Storage

Synergy unit bumpers have full storage throughout its width.

Tow Pin

The step is wide, tow pin and Synergy fold-down steps are all standard.

Safety Step

The Synergy fold-down step is ergonomically designed for safe entry.

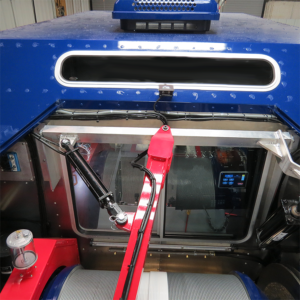

Sheave Window

Synergy incorporated a window above the hoist console to give the operator a view of the top sheave during wireline operations. This added safety feature allows the operator to view the top sheave without leaving the hoist console during any wireline operation to view the rig up of equipment.

Drum Counter

Synergy developed the drum counter safety feature that prevents the tool string from being retrieved from the well bore without the operator being aware of the tool string’s proximity to the surface. An encoder is mounted to the off-side stub shaft on the drum and counts the drum rotation going in and out of the well bore. The encoder can be set to stop the hoist at a predetermined depth from the surface. The maximum hydraulic speed can be set to give the operator more time for safe operations coming out of the well bore after any service is completed.

Interior Details - Power Enclosure

Synergy electricians meticulously position and label every wire in the power enclosure. This aids in training, troubleshooting and unit performance.

Rear Storage

Synergy maximizes storage utilizing 360 lb. capacity heavy duty slides. Slide plates are powder coated and standard on all rear storage boxes.

Upper Body Tool Racks

Synergy's tool rack system has four levels of tool storage. The full airbag system with securing chains provide maximum shock isolation during transport.

Handrails

Synergy builds our steps in-house with grip plate extrusion. Although strong, they are light weight and easy to extend or retract. Two LED spotlights and reflective tape on the steps are standard for safety while entering and exiting the logging cabin.

Battery Box

Synergy installs battery kill switches and a safety fuse block as standard components on all truck units. Synergy’s battery compartment space allows for proper battery cable routing, ease of troubleshooting or replacement.

Direct-Mount Hydraulic Tank

Synergy mounts the hydraulic tank directly to the truck chassis rails. The Synergy tank placement limits movement ensuring a secure mount and properly distributing the total weight.

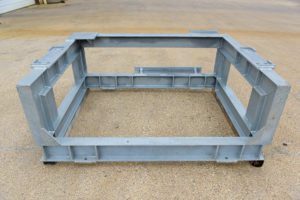

Reel Frame

Synergy builds reel frames from steel I-beam, gusseted at all key points and dip galvanized to prevent oxidation

Reel Frame Drip Pan

A full radius drip-pan is installed to allow for proper containment and draining of the line oil during operations.

Base Frame

Synergy's body mount is 0.75" aluminum bar welded, gusseted top and bottom. The body mount bolts to the chassis using 0.50" grade 8 bolts.

Body Mounts

Synergy's body mount is 0.75" aluminum bar welded, gusseted top and bottom. The body mount bolts to the chassis using 0.50" grade 8 bolts.

Exterior Details

Synergy rivets the wall skins every 4.00" to ensure a long cabin life and secure fit. Synergy utilizes exterior LED lighting standard on all trucks in accordance with in-country rules and regulations.

Under Body Storage Box Construction

Synergy's under body box construction is 3/16” aluminum throughout, welded and utilizes only stainless steel rivets.

Storage Seals

Quality seals are also standard on all Synergy trucks.

All Custom Truck Interiors

Full Service Manufacturer, Not an Assembler

With the exception of the cable reel, every fabricated component on our unit is built in house, to the highest possible standard.

This includes all truck interiors such as power enclosures, cabinetry, and cabin walls.

Facilities & Showroom

We build all our trucks on-site, right down to the very last detail, including the paint and exterior branding. Contact us to schedule a visit to our wireline truck showroom in Burleson, TX. We’d love to give you a V.I.P. tour of our entire facility and it’s capabilities.