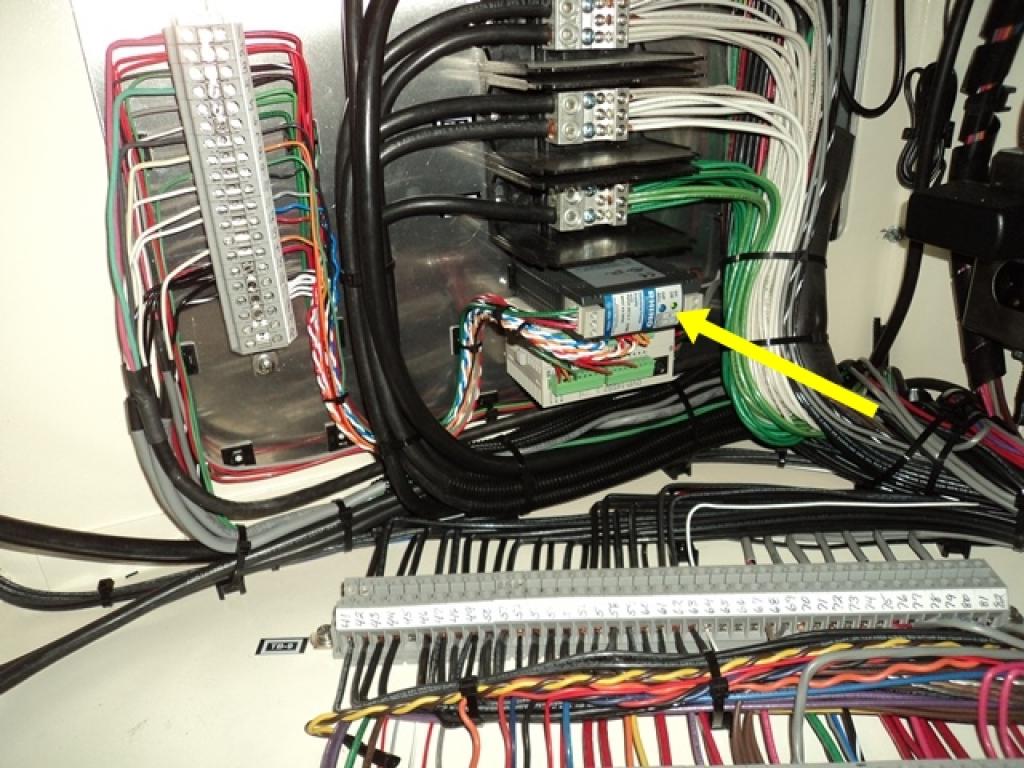

| Component Picture | |

|---|---|

| Transformers | |

| Transformers | |

| Component Related Documentation | |

| Safety Related Notes |

Transformers operate on the principle of electromagnetism and are used to change the voltage of current, either AC or DC, from one value to another – up or down - or to isolate portions of a circuit from surges. For example, a 460 volt supply can be reduced to 230 volts. The amperage changes in inverse proportion to the voltage change. When the voltage is reduced by half, the amperage will double. In the example given, if the 460 volt supply was rated for 10 amps, then 20 amps would be available at 230 volts. The opposite is also true. Thus, if the voltage is doubled, the amperage delivered will be reduced by 50%. Other proportions than 1:2 or 2:1 are available. Transformers consist of two coils, the primary coil and the secondary coil. The increase or decrease in voltage is proportional to the number of windings in the two coils. When current is flowing through the primary coil, an electromagnetic field is created which induces an electromagnetic field in the secondary coil, causing current to flow through the secondary coil. When the primary coil has more windings than the secondary coil, voltage in the secondary coil will be reduced. This is a “step down” transformer. The opposite is also true: in a step up transformer, the primary coil has fewer windings than the secondary coil and the output voltage is increased. Step down transformers are used to reduce the voltage in transmission lines for use by residences and industry. An example of a step up transformer is an ignition coil which boosts 12 volts to 75,000 volts or so. Transformers work only with AC current or DC current which is pulsed.

Before working on this machine, perform lockout-tagout procedures per the rules of your plant. Determine the sources of energy on this machine – electrical, pneumatic and hydraulic – and release or vent sources of stored energy – electrical capacitors, air receivers, and hydraulic accumulators. Shut off sources of power – electrical, pneumatic and hydraulic. Safely block mechanical sources of energy such as loaded springs and loaded machine members, or safely position the machine members so they are unloaded and springs are not under tension. Beware of hot hydraulic fluid and hot surfaces which can cause burns. Never “crack a hydraulic or pneumatic fitting” to check for the presence of stored energy. Hydraulic fluid injection injuries, as well as injection injuries from many other fluids, are extremely serious and must be treated immediately by medical personnel familiar with this type of injury. Loss of body parts or death may result from improperly treated fluid injection injuries! Never use your hands to feel for a hydraulic leak! Never use compressed air to blow dust off yourself or someone else – there is risk of an air injection injury. Review the schematics and think before proceeding to work on the machine to ensure you have made the machine safe to work on.

PWRS

Power Supply

N/A

1551944

N/A

N/A

This power supply is used to transform 12 VDC voltage to 24 VDC voltage for the pressure gauge display.