| Component Picture | |

|---|---|

| Relays | |

| Relays | |

| Component Related Documentation | |

| Safety Related Notes |

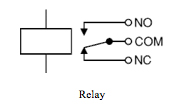

An electrical relay is an electrically controlled switch which is used to control large current flow using a relatively small current. Relays consist of a solenoid which controls a set of contacts. When the solenoid is powered on, its armature is drawn into the coil’s magnetic field, causing a set of contacts which are connected to a second circuit, to open or close. In practice, a low amperage, low voltage input signal can be used to control the current flow in a circuit which had high voltage, high current flow, or both high voltage and current. Relays can also be placed near the load device, such as an AC electric motor (in this case, the relay device is a motor starter), allowing the motor to be switched on and off using a relatively small switch placed at a remote location without needing to run relatively large wires to a large switch positioned at the remote location. This provides a cost savings in reduced wiring costs as well as reducing voltage drop through the wires.

Electromechanical relays can have multiple poles allowing the control of multiple circuits, can switch AC or DC current, are relatively inexpensive, resist voltage spikes, are available in sizes for low current to high current flow, but have limited operational life (250,000 actuations).

In comparison, solid state relays have only one set of controlled contacts, so they can control only one circuit, can switch only AC or only DC current and have a narrow frequency range. However, solid state relays have an operational life span of billions of actuations and operate very quickly.

Before working on this machine, perform lockout-tagout procedures per the rules of your plant. Determine the sources of energy on this machine – electrical, pneumatic and hydraulic – and release or vent sources of stored energy – electrical capacitors, air receivers, and hydraulic accumulators. Shut off sources of power – electrical, pneumatic and hydraulic. Safely block mechanical sources of energy such as loaded springs and loaded machine members, or safely position the machine members so they are unloaded and springs are not under tension. Beware of hot hydraulic fluid and hot surfaces which can cause burns. Never “crack a hydraulic or pneumatic fitting” to check for the presence of stored energy. Hydraulic fluid injection injuries, as well as injection injuries from many other fluids, are extremely serious and must be treated immediately by medical personnel familiar with this type of injury. Loss of body parts or death may result from improperly treated fluid injection injuries! Never use your hands to feel for a hydraulic leak! Never use compressed air to blow dust off yourself or someone else – there is risk of an air injection injury. Review the schematics and think before proceeding to work on the machine to ensure you have made the machine safe to work on.

KH1

Relay, Heater Control

N/A

N/A

0.10108

N/A

This relay is used to energize the cabin heater element.