| Diodes | |

|---|---|

| Diodes | |

| Component Related Documentation | |

| Safety Related Notes |

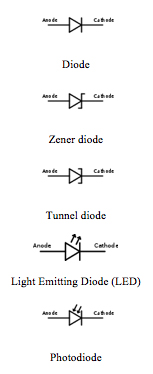

Diodes are two-terminal electronic components that conduct electric current in only one direction. The most common function of a diode is to allow electric current to flow in one direction while blocking current flow in the opposite direction. Diodes can be thought of as an electronic version of a hydraulic or pneumatic check valve. A common application for diodes is to convert, or “rectify” AC current into DC current. For this reason diodes are sometimes termed rectifiers. The positive terminal of a diode is termed the anode and the negative terminal is called the cathode. Forward bias is the term used to describe the current flowing through the diode from the anode to the cathode. Reverse bias is the term used when a diode blocks current from the cathode to the anode.

In addition to these basic diodes there are several other types of diodes. Zener diodes block reverse bias current up to a predetermined level. When that level is exceeded the diode allows the flow of current through the diode from the cathode to the anode.

Small signal diodes are typically used on circuit boards to change low amperage alternating current into direct current and to absorb voltage spikes.

Power rectifier diodes are used in alternators to rectify AC current into DC current.

Light emitting diodes, termed LEDs, convert current into light (photons) and, compared to standard light bulbs, are both rugged and very efficient, consuming very low amperage relative to the amount of light emitted.

Photo diodes are constructed of photosensitive material which increases in resistance as the light falling on the diode decreases. Thus, the diode conducts current when light strikes the diode. The more intense the light striking the diode, the lower the resistance to current flowing through the diode. Photo diodes are most often used to control the operation of outdoor lighting.

Before working on this machine, perform lockout-tagout procedures per the rules of your plant. Determine the sources of energy on this machine – electrical, pneumatic and hydraulic – and release or vent sources of stored energy – electrical capacitors, air receivers, and hydraulic accumulators. Shut off sources of power – electrical, pneumatic and hydraulic. Safely block mechanical sources of energy such as loaded springs and loaded machine members, or safely position the machine members so they are unloaded and springs are not under tension. Beware of hot hydraulic fluid and hot surfaces which can cause burns. Never “crack a hydraulic or pneumatic fitting” to check for the presence of stored energy. Hydraulic fluid injection injuries, as well as injection injuries from many other fluids, are extremely serious and must be treated immediately by medical personnel familiar with this type of injury. Loss of body parts or death may result from improperly treated fluid injection injuries! Never use your hands to feel for a hydraulic leak! Never use compressed air to blow dust off yourself or someone else – there is risk of an air injection injury. Review the schematics and think before proceeding to work on the machine to ensure you have made the machine safe to work on.

D2

Diode

69.6005

This diode is used to drain current from the hydraulic cooling fan when it is turned off.