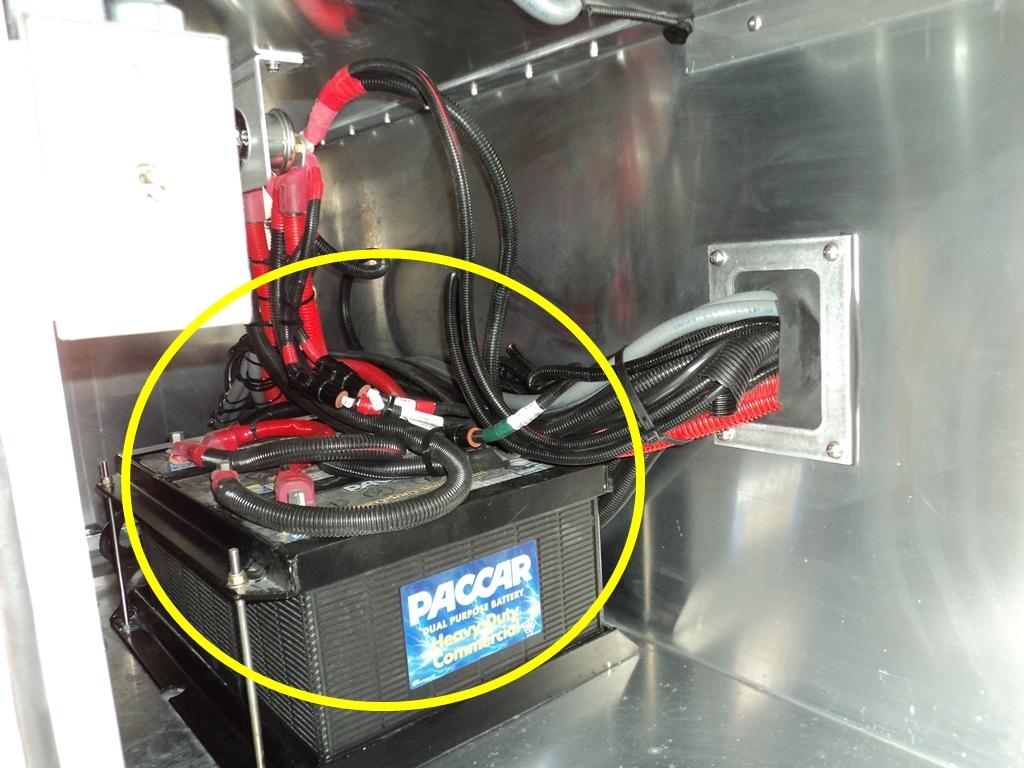

| Component Picture | |

|---|---|

| Battery Basics | |

| Component Related Documentation | |

| Safety Related Notes |

Batteries are devices which store electrical energy by converting the electricity into chemical energy. During this phase of battery operation the battery is said to be charging. When electricity is needed for uses such as powering the engine’s starter motor or for other functions, the battery is said to be discharging as the battery converts the stored chemical energy back into electrical energy. Most batteries used on mobile equipment are 12-volt lead-acid batteries comprised of six cells separated by partitions but connected electrically, all enclosed in a polypropylene housing. Each cell consists of lead plates, hardened with calcium or antimony, surrounded by an acidic electrolyte solution, a liquid which conducts electricity, and produces a little over two volts for a total of 12.6 volts. Plates with a positive charge are anode plates, which are coated with lead peroxide or lead dixoide and plates with a negative charge are cathode plates which are coated with a porous lead called sponge lead. Separators located between the plates prevent short circuiting by keeping the plates from touching each other. When a load is placed on the battery discharging it, sulfate molecules pass from the electrolyte to the plates while oxygen molecules pass from the anode plates to the electrolyte. The plate surfaces change to lead sulfate while the electrolyte changes to water. When the battery is charging, the opposite reaction occurs.

Before working on this machine, perform lockout-tagout procedures per the rules of your plant. Determine the sources of energy on this machine – electrical, pneumatic and hydraulic – and release or vent sources of stored energy – electrical capacitors, air receivers, and hydraulic accumulators. Shut off sources of power – electrical, pneumatic and hydraulic. Safely block mechanical sources of energy such as loaded springs and loaded machine members, or safely position the machine members so they are unloaded and springs are not under tension. Beware of hot hydraulic fluid and hot surfaces which can cause burns. Never “crack a hydraulic or pneumatic fitting” to check for the presence of stored energy. Hydraulic fluid injection injuries, as well as injection injuries from many other fluids, are extremely serious and must be treated immediately by medical personnel familiar with this type of injury. Loss of body parts or death may result from improperly treated fluid injection injuries! Never use your hands to feel for a hydraulic leak! Never use compressed air to blow dust off yourself or someone else – there is risk of an air injection injury. Review the schematics and think before proceeding to work on the machine to ensure you have made the machine safe to work on.

21

Battery

Chassis Battery

Chassis Battery

Chassis Battery

N/A

This battery is the supply power for all of the 12VDC circuits.