Pressure Reducing Valves

Component Related Documentation

A pressure-reducing valve is a normally open pressure control valve used to limit pressure in one or more branches of a hydraulic circuit. The reduced pressure in a circuit results in a reduced force being generated by the actuators in the controlled circuit. The pressure reducing valve maintains stable downstream pressure regardless of the upstream pressure or flow fluctuations. Pressure reducing valves control the pressure supplied to the actuator(s). The reduced pressure must be less than the pressure supplied by the main circuit. As pressure rises to the setpoint of a pressure reducing valve, the valve will modulate between an open and closed condition in order to control the downstream pressure. As a result, pressure reducing valves produce a moderate amount of heat during operation. Some pressure reducing valves will also vent, or relieve, downstream pressure spikes and are termed pressure reducing-relieving valves. Standard pressure reducing valves do not relieve downstream pressure spikes.

Safety Related Notes

Before working on this machine, perform lockout-tagout procedures per the rules of your plant. Determine the sources of energy on this machine – electrical, pneumatic and hydraulic – and release or vent sources of stored energy – electrical capacitors, air receivers, and hydraulic accumulators. Shut off sources of power – electrical, pneumatic and hydraulic. Safely block mechanical sources of energy such as loaded springs and loaded machine members, or safely position the machine members so they are unloaded and springs are not under tension. Beware of hot hydraulic fluid and hot surfaces which can cause burns. Never “crack a hydraulic or pneumatic fitting” to check for the presence of stored energy. Hydraulic fluid injection injuries, as well as injection injuries from many other fluids, are extremely serious and must be treated immediately by medical personnel familiar with this type of injury. Loss of body parts or death may result from improperly treated fluid injection injuries! Never use your hands to feel for a hydraulic leak! Review the schematics and think before proceeding to work on the machine to ensure you have made the machine safe to work on.

Troubleshooting Document

| Probable Cause | Possible Remedy |

|---|

| Contaminated fluid |

- Drain, flush and refill system

|

| Fatigue or broken spring |

- Inspect spring tension with tester.

- Remove and replace spring

|

| Plugged or restricted drain line |

- Check for crimped or collapsed line.

- Clean out line.

- Remove and replace line.

|

| Wrong spring |

- If available, check valve spring against dimensional drawing or request information from manufacturer

- Replace spring with new spring

- Replace reducing valve.

|

| Restricted orifice |

- Remove and clean

- Drain flush and refill system with filtered recommended fluid.

|

| Sticking valve spool |

- Remove and clean

- Drain flush and refill system with filtered recommended fluid.

- Clean and de burr spool

|

| Improperly adjusted |

- Check and readjust pressure.

|

| Worn spool seat or bore |

- Remove spool and replace

- Remove seat and replace

- Remove seat and replace valve.

|

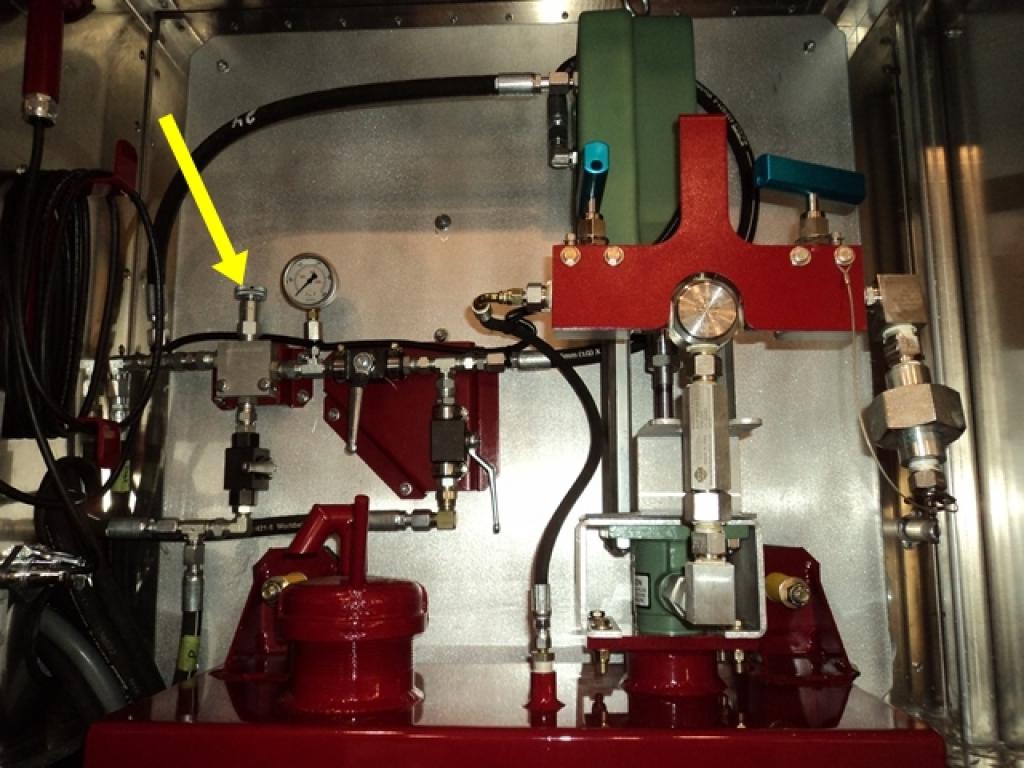

Item:

74

Description:

Pressure Reducing Valve

Manufacturer:

Part Number:

Stock Code:

0.88186

Electrical Address:

N/A

Component Application:

This pressure reducing valve is used to manually regulate the amount of system pressure to the hydraulic grease pump during manual operation of the grease pump.