Component Related Documentation

An inline check valve allows free flow in one direction and blocks flow from the opposite direction. Typically, the bodies of inline check valves are constructed of square or hex bar stock. The ports are located at opposite ends of the valve body and are therefore, in line with each other.

Safety Related Notes

Before working on equipment of any kind, perform lockout-tagout procedures per the rules of your plant. Determine the sources of energy on the machine – electrical, pneumatic and hydraulic – and release or vent sources of stored energy – electrical capacitors, air receivers, and hydraulic accumulators. Shut off sources of power – electrical, pneumatic and hydraulic. Be alert to the following:

1. Safely block mechanical sources of energy such as loaded springs and loaded machine members, or safely position the machine members so they are unloaded and springs are not under tension.

2. Beware of hot hydraulic fluid and hot surfaces which can cause burns.

3. Never “crack a hydraulic or pneumatic fitting” to check for the presence of stored energy. This may lead to a fluid injection injury. Injection injuries from fluids, are extremely serious and must be treated immediately by medical personnel familiar with this type of injury. Loss of body parts or death may result from improperly treated fluid injection injuries!

4. Review the schematics and think before proceeding to work on the machine.

5. Never assume that pressure has been eliminated.

Troubleshooting Document

| Probable Cause | Possible Remedy |

|---|

| Incorrect valve size |

- Change valve

|

| No or low pilot pressure |

- Check system pressure, increase as necessary.

- Check for collapsed pilot line.

|

| Leakage at plunger piston seal. |

- Disassemble and repair or replace

|

| Plunger piston binding |

- Disassemble and clean valve.

- Check for burrs on piston and/or bore.

|

| Poppet damage |

- Replace or refinish seat.

- Replace poppet.

- Check for excessive backpressure shock.

|

| Erosion |

- Drain, clean & flush system

- Refill system with filtered fluid

|

| Excessive leakage |

- Check leakage at cylinder at actuator of motor.

- See Troubleshooting Cylinder and Motors sections

|

| Broken spring |

- Disassemble and replace spring.

|

| Valve installed backwards |

- Reverse connection.

- Check free0flow direction indicator.

|

| No pump flow |

- See Troubleshooting Pump section.

|

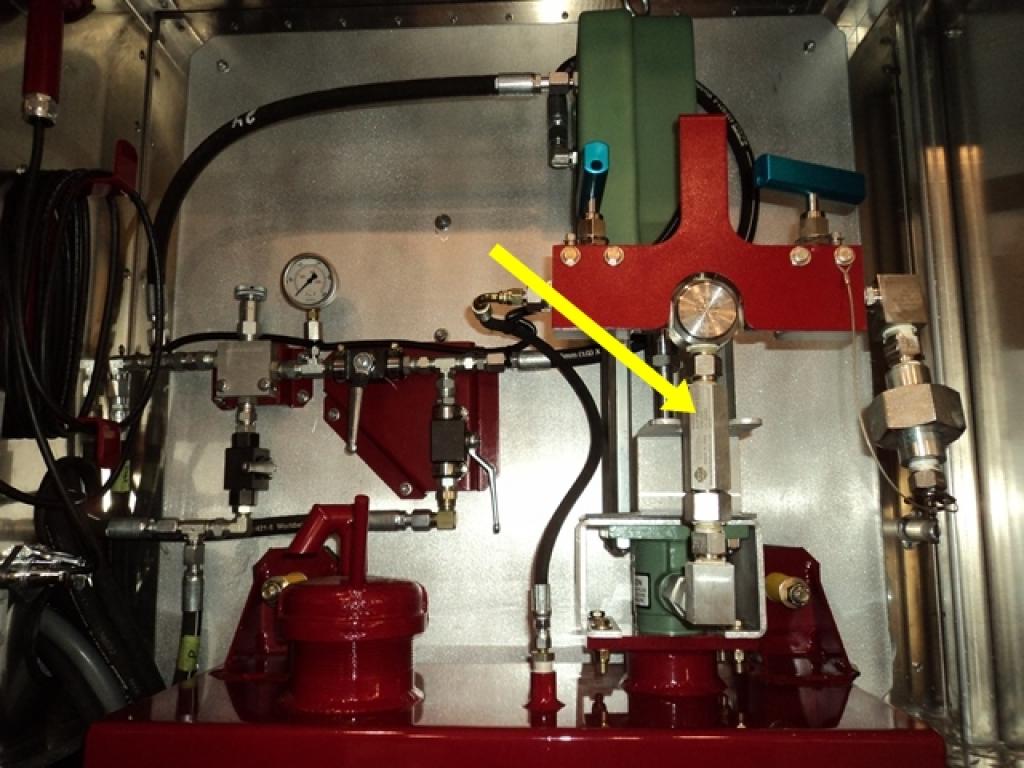

Item:

72

Description:

Check Valve

Manufacturer:

Part Number:

CV-NF8SS

Stock Code:

0.35028

Electrical Address:

N/A

Component Application:

This check valve is used to prevent back flow of grease into the grease pump.