Component Related Documentation

Cylinders are linear actuators. Their output force, or motion, is in a straight line. Their function is to convert pneumatic power into linear mechanical power. Their work applications may include pushing, pulling, tilting, and pressing. Cylinder type and design are based on specific applications. A tie rod cylinder is constructed of a steel cap end head, a steel barrel assembly, a rod end head, a rod bearing, a piston, and a piston rod. Tie rods and nuts hold the heads and barrel assembly together. Medium duty tie-rod cylinders generally have an aluminum cylinder barrel and anodized aluminum end caps. In order to smoothly move a load, multiply the load force by 1.3 to size the force to be developed by the cylinder. To move a load rapidly, multiply the load force by a factor of 2 before sizing the cylinder.

Safety Related Notes

Before working on this machine, perform lockout-tagout procedures per the rules of your plant. Determine the sources of energy on this machine – electrical, pneumatic and hydraulic – and release or vent sources of stored energy – electrical capacitors, air receivers, and hydraulic accumulators. Shut off sources of power – electrical, pneumatic and hydraulic. Safely block mechanical sources of energy such as loaded springs and loaded machine members, or safely position the machine members so they are unloaded and springs are not under tension. Beware of hot hydraulic fluid and hot surfaces which can cause burns. Never “crack a hydraulic or pneumatic fitting” to check for the presence of stored energy. Hydraulic fluid injection injuries, as well as injection injuries from many other fluids, are extremely serious and must be treated immediately by medical personnel familiar with this type of injury. Loss of body parts or death may result from improperly treated fluid injection injuries! Never use your hands to feel for a hydraulic leak! Never use compressed air to blow dust off yourself or someone else – there is risk of an air injection injury. Review the schematics and think before proceeding to work on the machine to ensure you have made the machine safe to work on.

Item:

21

Description:

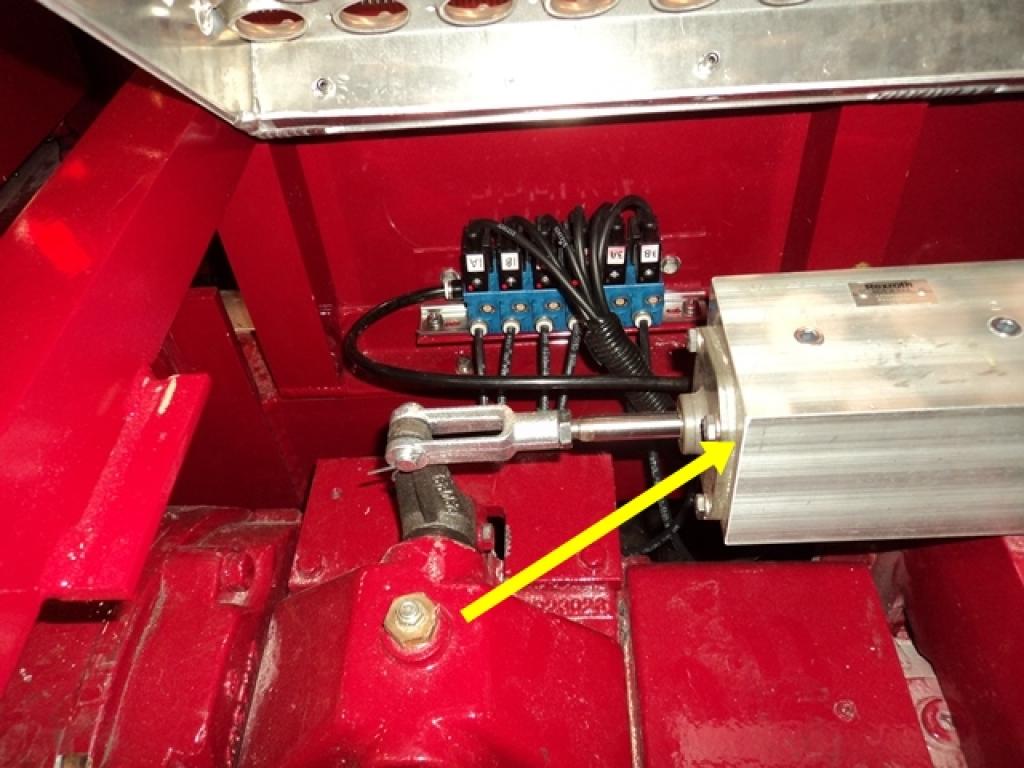

Shift Cylinder

Manufacturer:

Part Number:

Stock Code:

0.4049

Electrical Address:

N/A

Component Application:

This cylinder shifts the funk gear box to each selected gear.