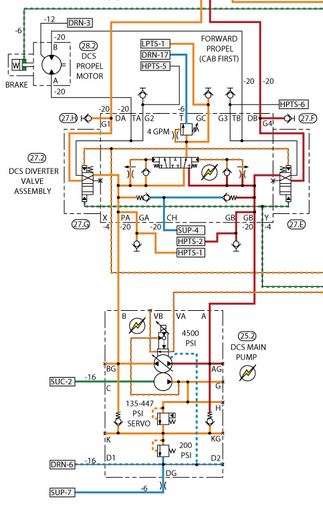

Hydrostatic drives circuit

Component Related Documentation

In a closed hydraulic motor circuit, one bi-directional pump controls one hydraulic motor. The pump does not have dedicated inlet and output ports. Instead, the ports are designated A and B and flow can be delivered by either port. Return flow from the motor flows into the port which is not delivering flow to the motor. The pump may be stroked to deliver flow from either Port A or Port B, thus controlling the direction of rotation of the motor shaft. A charge pump provides make-up oil to compensate for case drain leakage by the pump and motor. Cross-ported (A to B and B to A) load relief valves provide pressure protection for the system. Check valves prevent high pressure in the active circuit branch (A or B) from flowing back toward the outlet port of the charge pump. Typically, the charge pump also provides pilot pressure for the control which controls the swashplate position of the pump. Hydrostatic drives provide excellent control of rotational loads.

Safety Related Notes

Before working on this machine, perform lockout-tagout procedures per the rules of your plant. Determine the sources of energy on this machine – electrical, pneumatic and hydraulic – and release or vent sources of stored energy – electrical capacitors, air receivers, and hydraulic accumulators. Shut off sources of power – electrical, pneumatic and hydraulic. Safely block mechanical sources of energy such as loaded springs and loaded machine members, or safely position the machine members so they are unloaded and springs are not under tension. Beware of hot hydraulic fluid and hot surfaces which can cause burns. Never “crack a hydraulic or pneumatic fitting” to check for the presence of stored energy. Hydraulic fluid injection injuries, as well as injection injuries from many other fluids, are extremely serious and must be treated immediately by medical personnel familiar with this type of injury. Loss of body parts or death may result from improperly treated fluid injection injuries! Never use your hands to feel for a hydraulic leak! Review the schematics and think before proceeding to work on the machine to ensure you have made the machine safe to work on.

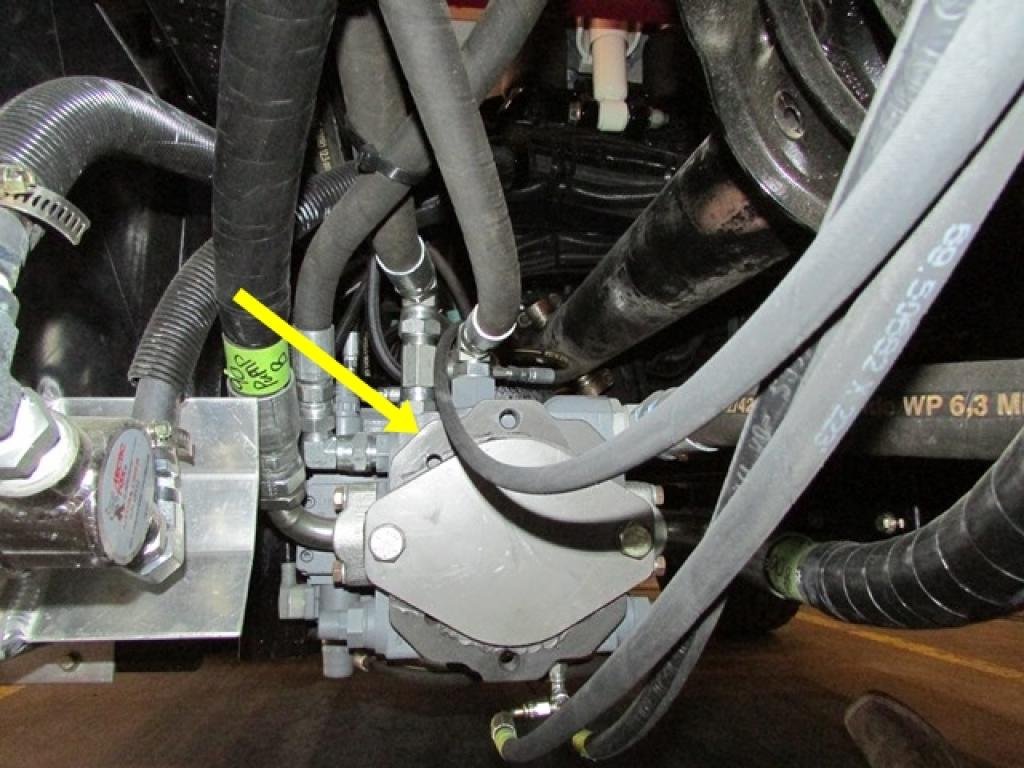

Item:

1

Description:

Winch Pump

Manufacturer:

Bosch Rexroth

Part Number:

AA4VG90EP1DT1/32L-NUF52F071-DHS \\\"U\\\" Shaft SAE-C # R902075896-001

Stock Code:

0.40062

Electrical Address:

N/A

Component Application:

The pump used in this application has a proportional electrical control valve which receives a variable command signal from the control joystick, through a driver card, to bring the pump on and off stroke. The pump stroke is linear to the variable command signal received. NOTE--PUMP SETTINGS: Charge Pressure Setting=470PSI, Pressure Override Setting=5,075PSI, Cross-Port Pressure Relief Valve "A & B"= 5,800PSI