Sequence of Operations

Sequence of Operations

Sequence of Operations Sequence of Operations

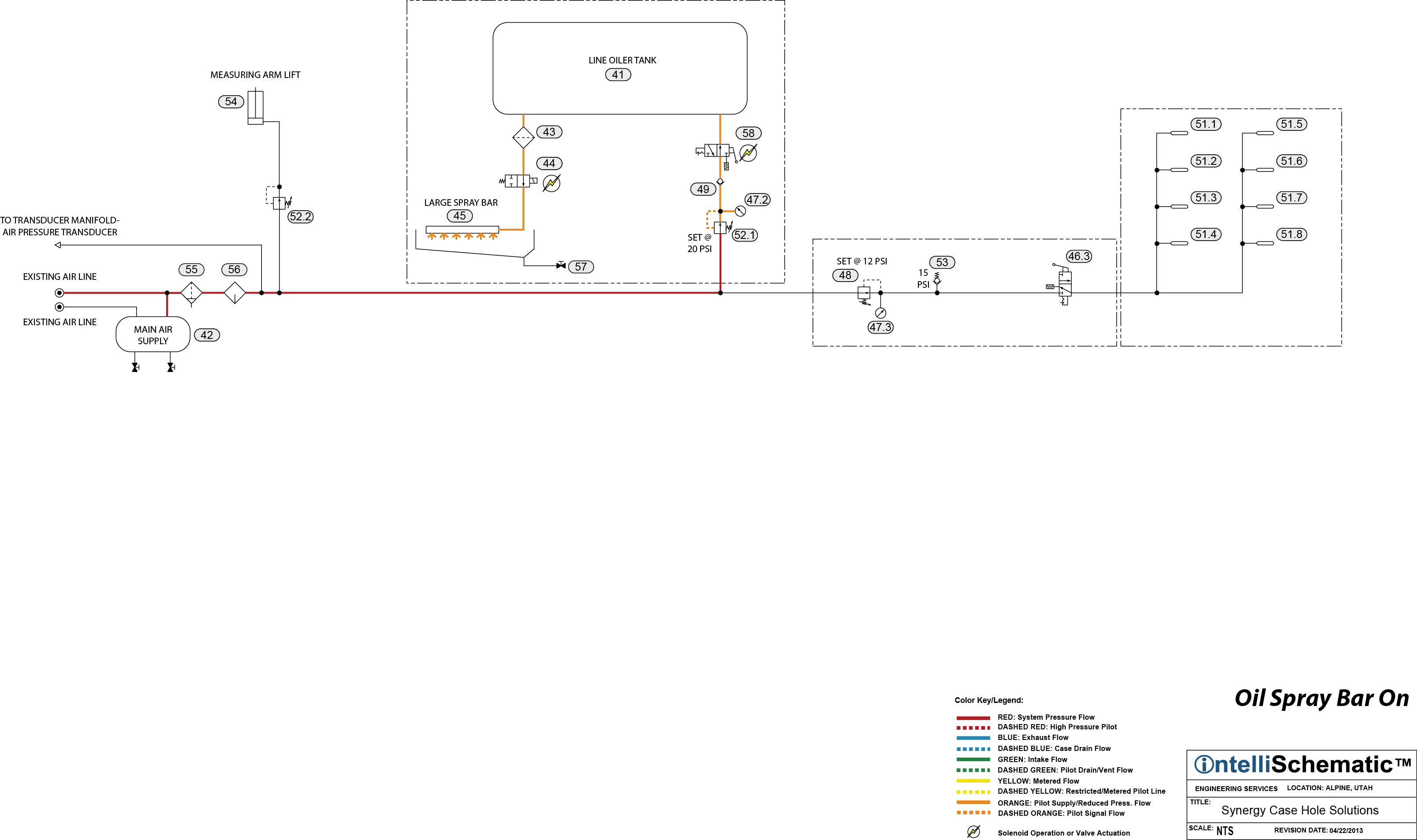

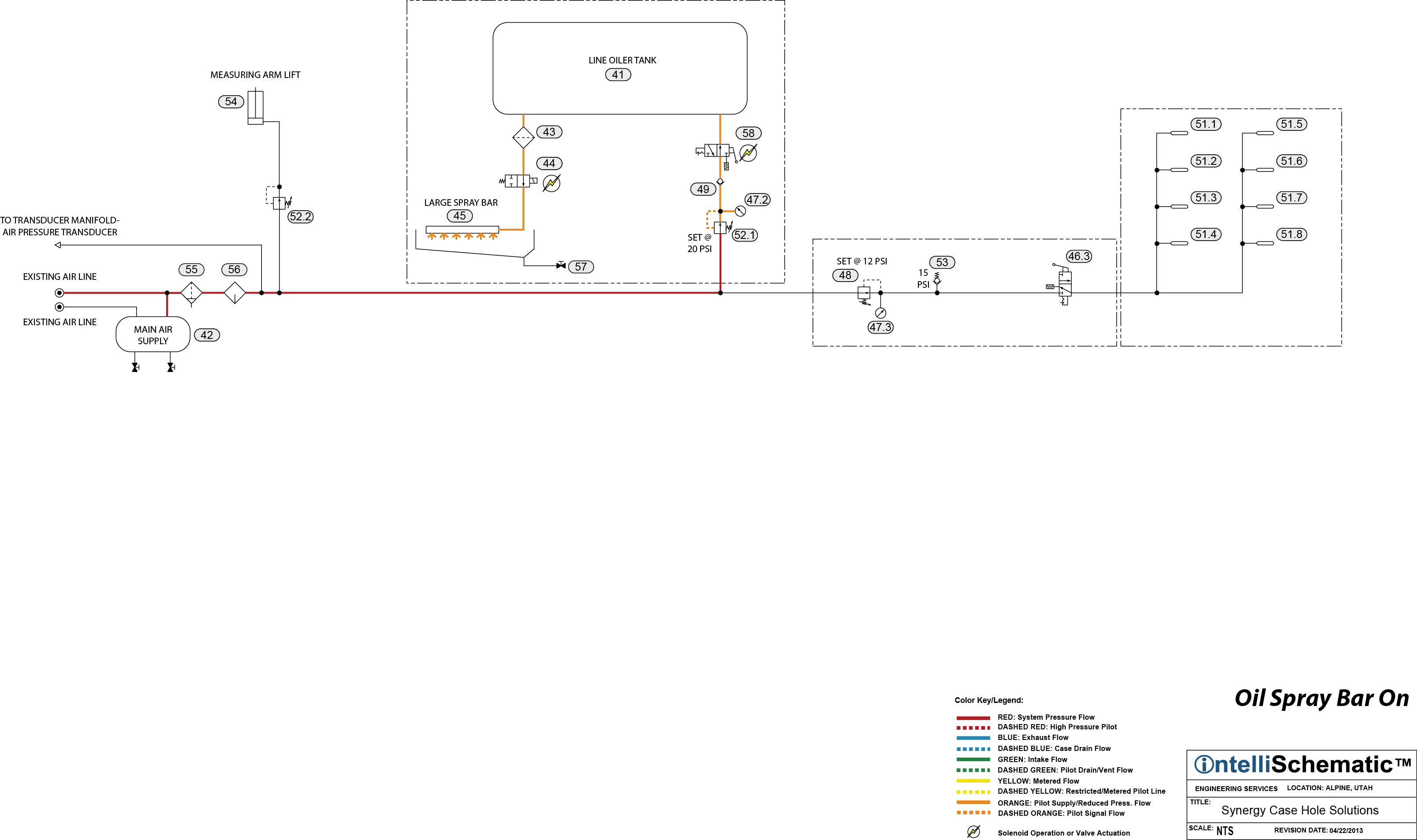

| Oil Spray Bar On |

1. Ensure that Line Oiler Ball Valve (55) is positioned towards the large reel setting.

2. Air pressure flows through Air Filter (55) and oil is injected into the system as it flows through Oiler (56).

3. When the Directional Control Valve (58) is positioned to the “On” position, pressurized air flows through Pressure Reducing Valve (52.1).

4. Pressure exceeding the spring setting of the Pressure Reducing Valve (52.1) will cause that valve to shutoff and not allow the pressure to exceed the setting.

5. Air pressure can be viewed at gauge (47.2).

6. Reduced air pressure then flows through check valve (49) and passes through the Flow Control Valve (68) which pressurizes the Line Oiler Tank (41).

7. When the Line Oiler Control Valve (44) is energized by the operator, pressurized line oil flows through filter (43) and then through the Control Valve (44).

8. Pressurized line oil passes through Spray Bar (45) and is applied to the wire that is wound on the drum.